Should costing

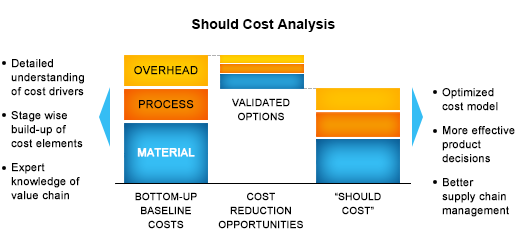

Understanding what a product/component would cost, when produced, during early stages will help manage its costs better. In order to get it accurately, we bring together our deep capabilities in manufacturing engineering, process planning and tooling to do cost estimation (Should Costing). Should costing compliments product Development, manufacturing and sourcing functions.

This crucial function is staffed with domain experts having rich experience in manufacturing and supported by enabling technology and tools.

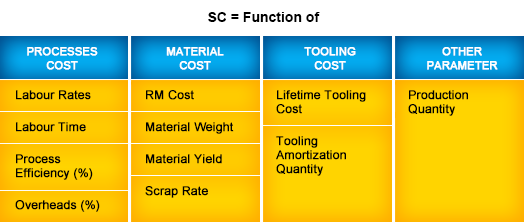

Should costing scientific approach

Our team of engineers develop cost models based on activity based methodology. For this, our engineers work with customers to understand the part/product and define accurate, practical and manufacturing realistic process and planning. Process plan thus derived is critical to get accurate costs and the costs are classified into Manpower, Machines, Methods (Process, Measurements, Materials, Tooling) and Miscellaneous (Overheads).

Our services could help customers at various stages of product life cycle and can be classified as:

- Concept should costing: helps understand what the concept could cost when realized.

- Development should costing: helps with cost out opportunities during the development stage

- Should costing: helps with sourcing and continuous cost reduction initiatives

Key Features

- Comprehensive analysis of processes & technologies for possible optimization ( i.e. Labour, Cycle time)

- Modular and activity based approach to costing with proprietary templates

- Knowledge base, Strong database and matured methodology & processes

Benefits to Customer

Concur's Should costing solutions deliver value to customer across the lifecycle. Our teams have helped customer in realizing benefits in bettering target costs, reduce manufacturing and supply-chain costs and avoid costs during design phase:

- In an complete machinery development involving 600 designed parts - a saving of $15000 was achieved.

- Gear box design was achieved with 22% lower costs compared to competing product

Inputs Required

- Detailed specifications (depending on the lifecycle of the product)

- Early in the cycle

- Concept sketches

- Functional & Performance Specs

- Material & planned process

- Development Cycle

- Detailed drawings

- All documents of early cycle

- Sourcing & continuous improvement

- Constraints

- All documents of development cycle

Deliverables

- Should costing report

- Process documentation

- Routing

- Setup

- Machine & run time on it

- Process time

- Tooling Sheets

- Material data sheets